20 March 2025

Fermentation-produced Chymosin coagulant

Are you striving to optimize whey value, taste, texture and sliceability – all in an efficient and sustainable way?

Our Maxiren® vegetarian rennet allows you to meet all these needs while delivering a well-controlled proteolysis that meets not only consumer needs but also the highest industrial standards in efficacy, taste and texture.

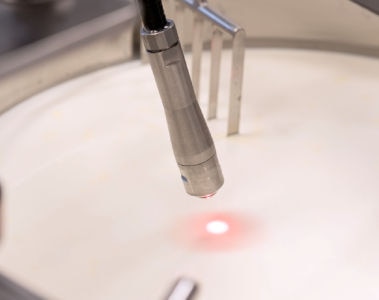

Maxiren® features a portfolio of 100% pure chymosin enzymes produced by fermentation and includes products with different levels of milk clotting activity. This includes Maxiren® XDS - our latest innovation in cheese coagulants, available in both liquid and granulated versions.

By working with our cheese experts you can calculate the optimal degree of coagulation required for your individual products, thus unlocking your ability to optimize processes, cut costs and reduce your carbon footprint – all while maintaining (and indeed improving) cheese quality.

High specificity and low proteolysis makes Maxiren® the coagulant of choice.

High specificity and reliable coagulation translated into more flexibility for cheesemakers.

Improve yield with less moisture loss, no cutting loss, and less labor.

Improve plant efficiency and flexibility and reduce your carbon footprint.

Our core cheese enzyme portfolio is completely benzoate-free.

Maxiren® XDS is our latest innovation in cheese coagulants. This bovine chymosin was created specifically to deliver extended textural shelf life in cheese while maintaining lower proteolysis. With the highest specificity on the market, Maxiren® XDS gives you improved texture and sliceability - thus improving plant efficiency and reducing your carbon footprint.

Especially suited for mozzarella, cheddar and string cheese, this coagulant gives you greater efficiency and flexibility in production so that you are no longer up against the clock at every stage. As the texture of the cheese is retained, shredding, dicing, and slicing can take place effortlessly and efficiently at any point in the shelf life.

20 March 2025

25 November 2024

11 October 2024